Purchasing from Neoden USA entitles you to specific instructional movies, manuals created in-property by our engineers and complex assistance via Zoom, mobile phone, e-mail and in individual.

The advancements in automation, The shortage of certified manual assemblers for PCB’s along with the reshoring of PCB assembly from overseas to your US can make this a good time To guage convey SMT and PCB assembly back again in dwelling.

This segment has promotional content. You should enable improve it by getting rid of advertising language and inappropriate exterior inbound links, and by including encyclopedic text created from a neutral viewpoint. (June 2016) (Learn how and when to remove this message)

Exceptional Throughput: These machines are ideal for significant-volume manufacturing, as they can concurrently Focus on 4 PCBs, considerably rising the output.

Customer Merchandise: Pick and Place machines are employed within the creation of a wide array of buyer merchandise, such as property appliances, gaming consoles, and intelligent household gadgets.

Each nozzle is precisely aligned using a significant-resolution CCD digicam to ensure that pick and place coordinates for all nozzles could be determined and altered with a single image. Shop air isn't necessary for this machine as Every single nozzle is driven by a focused interior vacuum pump technique.

It can be done to make placement packages (also known as a ingredient placement list (CPL file) or XY centroid info) from Gerber facts but this can be very time consuming and there is a high possibility of mistakes developing.

The part placement process is made of picking Each and every ingredient subsequently from the feeder employing a nozzle and transporting for the programmed place.

Element sizing and place – Hugely populated types could have tiny components positioned near to more substantial factors which should be taken into account when producing the placement software.

This consists of info for instance monitoring, solder resist, silk monitor and drill facts and is particularly essential for the bare PCB to be created.

Dual-Head Machines: Dual-head configurations are adaptable and well suited for pick-and-place machine moderate to higher-quantity creation. They strike a equilibrium involving pace and precision, creating them a typical preference in lots of electronics producing amenities.

From your high speed machine, the board transits to the precision placement machine. These pick-and-place machines often use high resolution verification cameras and high-quality adjustment programs via substantial precision linear encoders on Every single axis to place parts additional precisely compared to the substantial-pace machines. On top of that, the precision placement machines are able to managing greater or maybe more irregularly formed components such as large package deal integrated circuits or packaged inductor coils and trimpots. Contrary to the rapid placers, precision placers commonly don't use turret mounted nozzles and instead depend on a gantry-supported moving head.

Cost-effective handbook pick & place and dispenser system for short run and prototype assembly of printed circuit boards.

Programming Adaptability: Offline programming permits operators to develop and good-tune placement courses without having interrupting the machine's manufacturing. This overall flexibility is crucial when adapting to various PCB types or making system adjustments for distinct part sorts.

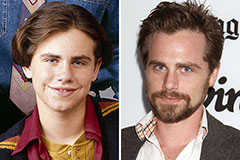

Rider Strong Then & Now!

Rider Strong Then & Now! Daniel Stern Then & Now!

Daniel Stern Then & Now! Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Shane West Then & Now!

Shane West Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!